ASPICE® : from Training to Certification

What is ASPICE ?

ASPICE challenge

In the modern automotive landscape, embedded software has become critical, steering customer choices beyond traditional factors like horsepower. Today, consumers consider innovative electronic and software features, such as ADAS capabilities or infotainment systems, when making decisions. Software-driven advancements are reshaping the industry, necessitating a standardized approach among stakeholders (OEMs, Tiers 1, and Tiers 2 suppliers).

While ISO 26262 addresses software safety, ASPICE steps in to handle broader elements, including management, support, and non-safety-related embedded software. At the end of the supply chain, OEMs desire a standardized reliability approach, ensuring homogeneity across the entire supply chain.

Why ASPICE ?

Automotive Software Performance Improvement and Capability dEtermination (ASPICE) offers a framework for defining, implementing, and evaluating processes in system development, with a particular focus on software components. Major OEMs globally have adopted ASPICE to enhance product quality, reliability, and assess supplier process capabilities. ASPICE supports the quality of the customer’s daily processes and also takes into account the cost and schedule implications of product development.

ASPICE for system makers

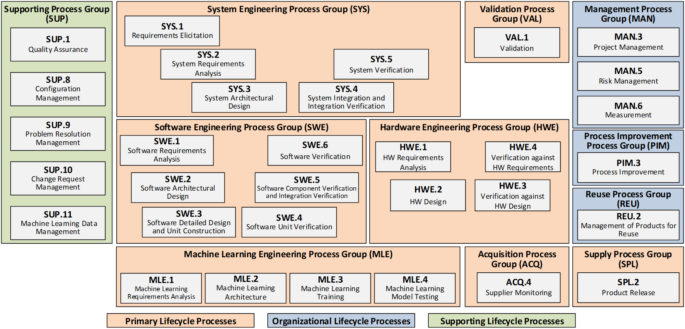

For suppliers, the prospect of achieving ASPICE may initially seem daunting. However, similar to other software norms, it is segmented into categories and groups, allowing for separate development to simplify the initial connection:

- Primary: encompasses the entire production part of the project, starting with the acquisition group for commercial agreements and environmental aspects. It then extends to production, involving supplier management if required, along with system and software development. These last two groups follow the V-cycle, a common practice in software development. In Version V4.0 of ASPICE, it also includes HW engineering and ML engineering.

- Supporting: Anything not constituting a product but vital for a high-quality product falls into this category. Supporting aspects here are generic for product (system, software, hardware, machine learning) development, including configuration management, change control, quality management, documentation, etc. These principles are well-established in the software industry and require simple adaptation to comply with ASPICE requirements. Some elements from this category are covered in ISO 26262 part 8.

- Organizational: Every project requires a minimum level of organization, and ASPICE concentrates on this aspect within this category. It involves the development of processes related to management (including risk management) and improvement and reuse processes.

Automotive SPICE Process Reference Model – Overview V4.0

ASPICE, based on these categories and groups, gives processes base practices in details and the applying company shall demonstrate compliance to them. Therefore, they are part of the performance indicators. In addition to these indicators, the generic practices will be part of the capability indicators. The assessor will use both indicators to validate and conclude the capability level from level 0 incomplete process to level 5 innovating process.

The Process Assessment Model is based on two axes:

- The Measurement Framework, aligned with ISO/IEC 33020, defines capability levels (from Level 0 to Level 5) and process attributes (e.g., PA1.1, PA2.1, PA2.2, etc.), which serve as process capability indicators.

- The Process Reference Model outlines domains and scopes, process purposes, and process outcomes, including base practices and work products. These constitute the process performance indicators.

Our offering

ASPICE answers all these problems at once. It can be worked in addition to the ISO 26262 or stand-alone. This standard gives guidance and requirements for the process development and the assessment of these processes through indicators definition and measurement methods.

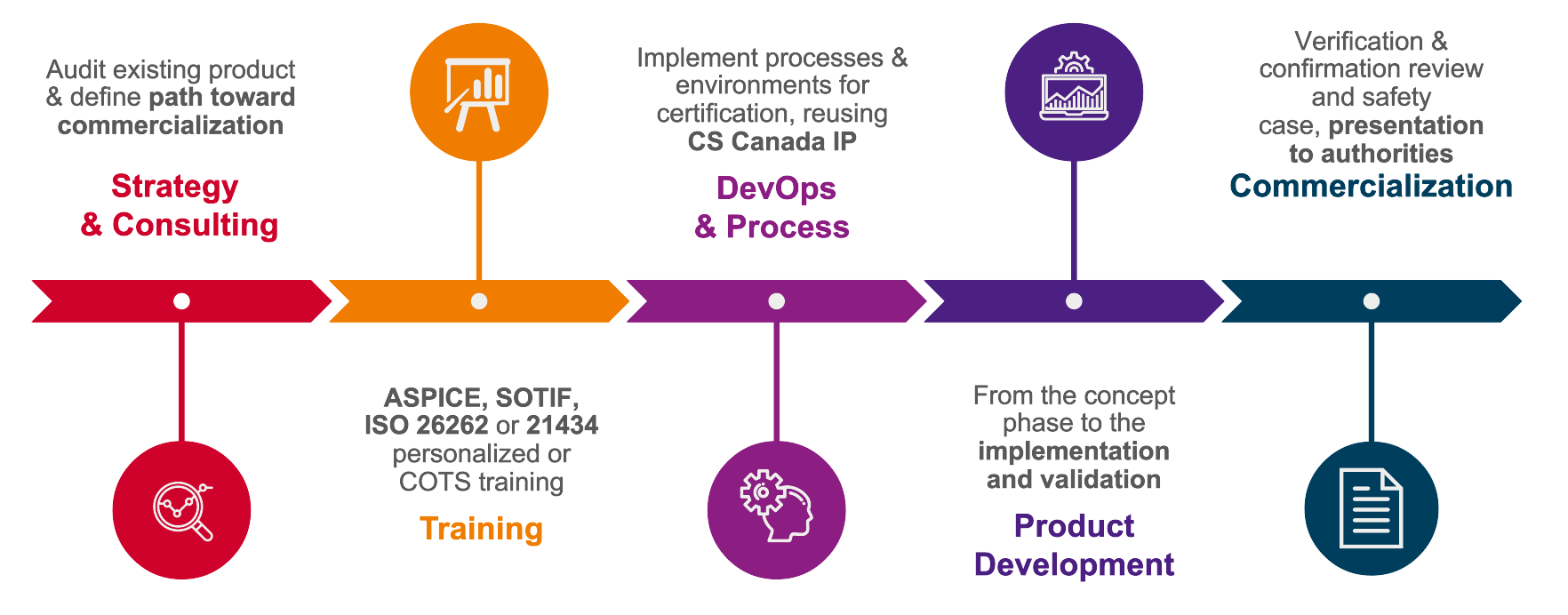

To start with this standard, CS Group Canada proposes the

following customer journey:

COTS or personalized ASPICE training to introduce the norm, familiarize with ASPICE vocabulary and structure, have a better view of what is awaited to be compliant, target the proper level for the existing, to be developed or under development product

CS Group Canada multidisciplinary auditing team works offline and with you to identify the product and company situation regarding the standard. At the end of this analysis, the customer knows how far he is to reach the required level of assessment. A detailed report is used as a start to improve process, method, and product.

Some of the activities can be tough to create from scratch, or there is not enough staffing to do the job, or the employees need to stay focus on developing the software. In these situations, CS Group Canada can help develop, implement a portion of it: write processes, create templates for assessment, create documentation, etc. using our proprietary IP to speed up the process.

- CS Group Canada can support the preparation phase ahead of the external assessment by conducting a full internal evaluation or targeted audits to effectively prepare your organization for ASPICE requirements.

- During the external assessment itself, we can either support your team throughout the process or act as the Principal Assessor, in full compliance with the ASPICE model.

After the assessment, CS Group Canada stays connected with the customer to help him improve and reach the higher level of assessment through expertise meetings or detailed training for specific processes.

Why consider CS Canada?

Proven Track Record:

Expertise in various standards as ISO 26262, UL 4600, ISO 13849, ISO 21434 and an extensive experience on technologies development for System, Software and Hardware engineering.

Field-Proven Expertise:

Beyond our knowledge of industry standards, we draw on hands-on experience in the development of complex systems. This close connection to real-world industrial challenges allows us to offer practical, implementable solutions tailored to your environment. Our approach is constructive and grounded: we take the time to understand your constraints, build on your existing strengths, and move forward together. Rather than pushing disruptive changes, we focus on tailored support built on dialogue, trust, and efficiency.

Commitment to Excellence:

We stay ahead of the curve, ensuring you benefit from the latest best practices and industry standards. Moreover, we’re partnering since +25 years with top US and Canadian OEM, Tier 1/2 and high-tech start-ups.