ISO 26262 Checklist and Compliance Templates

What is ISO 26262 ?

ISO 26262 is a crucial global standard for managing functional safety in the automotive industry. It outlines a systematic approach for regulating product development across system, hardware, and software levels. Covering the entire product lifecycle, from concept to decommissioning, it helps assess acceptable risk levels for components and systems while documenting the testing process. By implementing ISO 26262, companies ensure a common safety standard and vocabulary to measure and communicate system safety.

Accelerate your Gap Analysis & Compliance process

Our ISO 26262 plans and standards templates simplify compliance with essential automotive safety standards. Tailored to align with the 2018 edition of ISO 26262, this template seamlessly integrates required work products and workflows into your product development process.

Built to meet the needs of automotive OEMs and their suppliers, it offers a ready-made solution for designing high-quality automotive hardware and software that conform to critical safety and quality regulations with safety levels up to ASIL D.

ISO 26262 Available Plans & Standards Templates

- Organization-specific rules and processes

- Quality Management System

- Impact Analysis

- Safety Planning

- Item definition

- Hazard Analysis and Risk Assessment (HARA)

- Functional Safety Concept (FSC)

- Functional Safety Requirements (FSR)

- Technical Safety Concept (TSC)

- Technical Safety Requirements (TSR)

- System architectural design

- Hardware-Software Interface (HSI)

- System integration, testing and validation

- Hardware Safety Requirements (HSR)

- HW Design

- HW Safety Analysis

- FMEDA – SPFM & LFM

- FMEDA – PMHF

- Hardware integration and verification

- Software Development Environment

- Software Safety Requirements (SSR)

- Software architectural design

- Dependant Failures Analysis (DFA)

- Software unit design, testing, verification, implementation and integration

- Production plan

- Production control plan

- Production process capability report (PPAP)

- Service plan

- Distributed development

- Specification and management of safety requirements

- Configuration and change management

- Documentation, traceability, verification, evaluation, integration

- ASIL Determination and Update

- Dependant Failures Analysis (DFA)

- Safety analyses report

- Hazard Analysis and Risk Assessment (HARA)

- Vehicle integration

- Safety validation

A bridge connecting ISO 26262, ISO/SAE 21434, and ASPICE

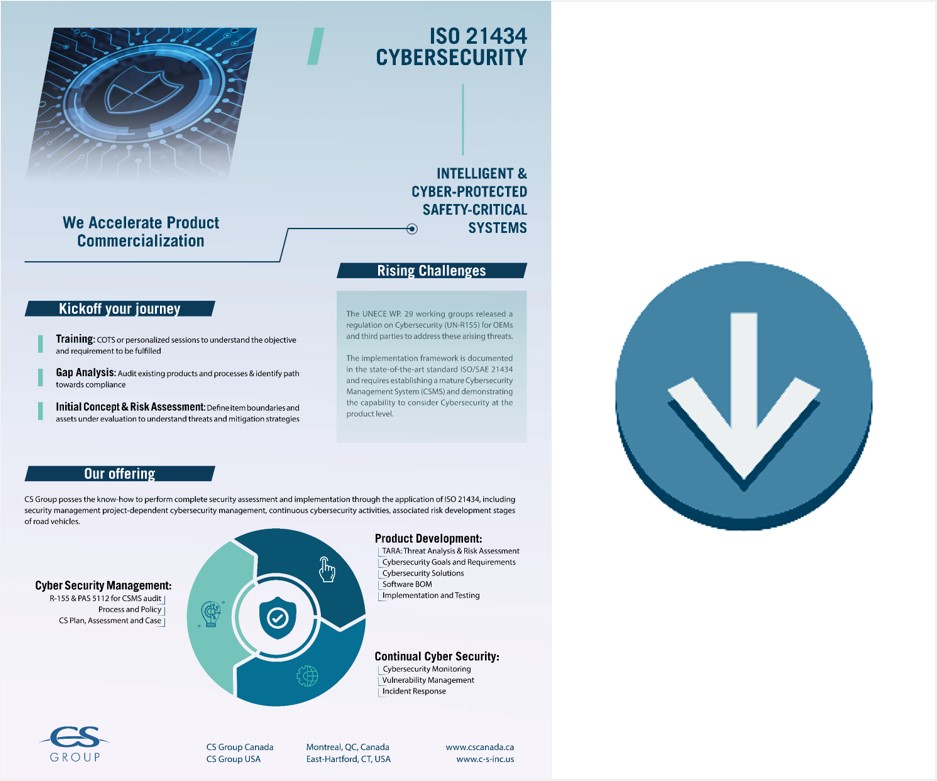

Automotive Cybersecurity ISO/SAE 21434

ISO 21434 and ISO 26262 share a common goal of secure, safe automotive systems. Their processes align in risk assessment, lifecycle management, and validation, enabling streamlined efforts toward both cybersecurity and functional safety. We can provide similar templates on:

- Project Management Process and Documentation

- Supporting Processes

- Quality Processes

- Supply Processes

- System and Software Engineering processes and analysis

- Cybersecurity Specific templates and checklist

ASPICE

ASPICE and ISO 26262 complement each other in ensuring high-quality, safe automotive systems. Their aligned processes in lifecycle management, assessment, and validation foster a streamlined approach to both software quality and functional safety. We can provide similar templates on:

- Management processes

- Supporting processes

- Supply Processes

- System and Software development processes

- ASPICE specific templates and checklist

Need more information?

Why concider CS Canada ?

To meet ISO 26262 challenges, CS Canada has assembled a highly skilled team with substantial experience in critical real-time software development and V&V. More specifically, this team has:

- Provided system/safety expertise to automotive industry in the development of advanced driver assistance functionality for 7+ years.

- Adapted proven methods and techniques from the verification of critical aerospace software for use in development of high ASIL automotive systems.

- A capability to use advanced methods and tools (e.g., formal methods) to meet the challenges of increasingly complex software in automotive applications.

- Extensive experience with DO-178 certification of more than 30 airborne software programs.

- Trusted by over 50 North American companies (US and Canada).